Pump Alignment and Laser Shaft Alignment Services by Panpush Laser Alignment FZE

Introduction

In the world of industrial machinery, proper alignment is crucial for optimal performance and durability. One area where alignment plays a critical role is in pumps. Pump alignment refers to the precise positioning of the pump and its associated components to ensure efficient operation and minimize wear and tear. This article will explore the importance of pump alignment and laser shaft alignment services, with a focus on the expertise provided by Panpush Laser Alignment FZE.

Understanding Pump Alignment

Definition of Pump Alignment

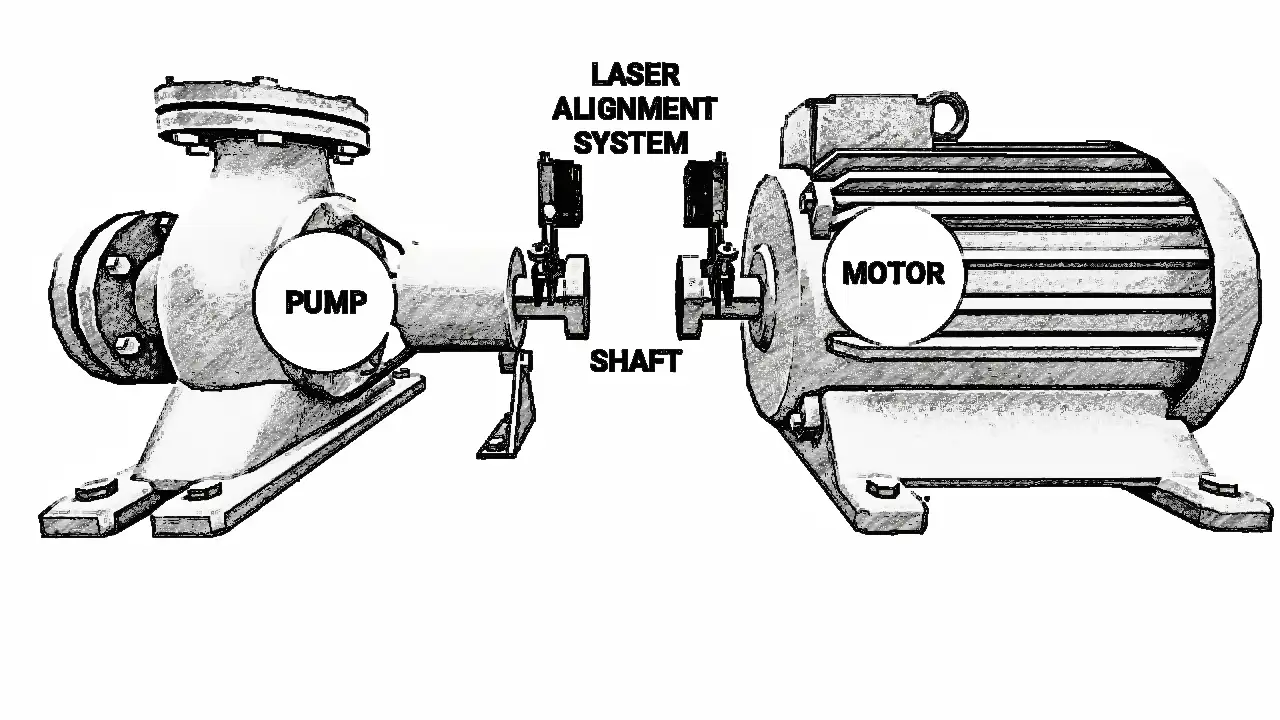

Pump alignment involves aligning the pump’s rotating shaft with the motor or driver shaft. It requires adjusting the position and angular orientation of the pump to achieve perfect alignment. Proper laser alignment is essential to prevent various issues that can negatively impact performance and increase maintenance costs.

Why Pump Alignment Matters

When a pump is misaligned, it can lead to excessive vibrations, which affect its performance and longevity. Vibrations cause premature wear and tear on the pump’s components, including bearings and seals. Moreover, misalignment increases energy consumption, resulting in higher operating costs.

Consequences of Poor Pump Alignment

Poor pump alignment can have several detrimental effects. It can cause excessive noise, increased vibrations, and reduced pump efficiency. These issues can lead to frequent breakdowns, higher maintenance expenses, and production downtime. It is crucial to address alignment problems promptly to avoid these costly consequences.

Laser Shaft Alignment: A Precise Solution

Introduction to Laser Shaft Alignment

Laser shaft alignment is an advanced method used to achieve precise alignment for pumps. It utilizes laser technology to accurately measure and correct misalignment between the pump and the motor or driver. Compared to traditional or dial gauge alignment methods, laser shaft alignment offers unparalleled precision, efficiency, and reliability.

Advantages of Laser Shaft Alignment

Laser shaft alignment offers several advantages over traditional or dial gauge alignment methods. Firstly, it provides real-time measurements and visual representations of misalignment, allowing engineer to make precise adjustments. Secondly, laser alignment eliminates guesswork and reduces human error, ensuring accurate results. Lastly, the speed and ease of laser alignment shorten the overall alignment process, minimizing downtime.

Panpush Laser Alignment FZE: Leaders in Pump Alignment Services

Introduction to Panpush Laser Alignment FZE

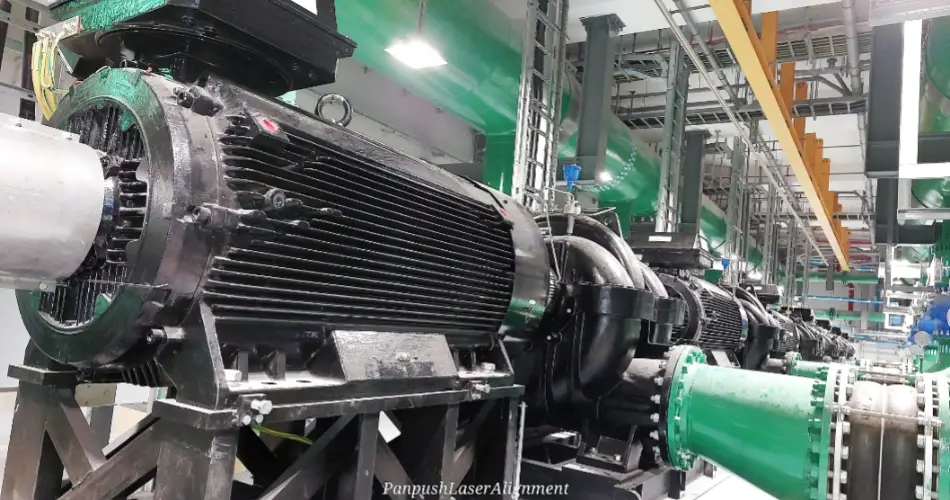

Panpush Laser Alignment FZE is a trusted provider of pump alignment and laser shaft alignment services in UAE. With our expertise and equipment, we have established ourselves as industry leaders. Our laser alignment specialized engineer possesses extensive experience in aligning various types of pumps for diverse industries.

Overview of Pump Alignment Services

Panpush Laser Alignment FZE offers comprehensive pump alignment services. We employ advanced laser alignment systems and techniques to achieve precise alignment results. Our services encompass the alignment of various types of pumps, including centrifugal pumps, reciprocating pumps, and gear pumps.

Experience and Expertise in Laser Shaft Alignment

Panpush Laser Alignment FZE specializes in laser shaft alignment, ensuring accurate alignment for pumps of all sizes and complexities. Our engineer participate in comprehensive training programs and consistently upgrade their skills with the latest alignment techniques and technologies. With our expertise, we can efficiently handle alignment projects in industries such as water treatment, oil and gas, manufacturing, and more.

The Process of Pump Alignment

Achieving proper pump alignment involves a systematic approach. The following steps clarify the pump alignment process:

Step 1: Initial Assessment

The alignment process begins with a thorough assessment of the pump and its surrounding components. Laser alignment specialized engineer inspect the condition of the pump, evaluate its alignment status, and identify any existing issues or misalignment.

Step 2: Preparations

Before commencing the alignment process, engineer ensure the pump and surrounding area are clean and free from debris. They also secure the necessary tools and equipment required for laser shaft alignment.

Step 3: Measurement

Using laser alignment systems, engineer measure the existing misalignment between the pump and the motor or driver. The laser systems provide accurate readings of both angular and positional misalignment.

Step 4: Adjustment

Based on the measurements, engineer make precise adjustments to align the pump correctly. This may involve shimming, repositioning, or realigning the motor or driver.

Step 5: Verification

Once the adjustments are made, laser alignment specialized engineer recheck the alignment to verify that the pump is aligned within the specified tolerances. They use laser alignment systems to ensure accurate alignment results.

Step 6: Documentation

A comprehensive alignment report is generated, documenting the initial misalignment, the adjustments made, and the final alignment measurements. This report serves as a reference for future alignment checks and maintenance activities.

Benefits of Professional Pump Alignment

Professional pump alignment services, such as those offered by Panpush Laser Alignment FZE, deliver several benefits:

Improved Pump Performance and Efficiency

Proper alignment ensures that the pump operates at its optimal capacity, resulting in improved performance. Aligned pumps experience reduced vibrations, which lead to smoother operation, increased reliability, and enhanced energy efficiency.

Extended Equipment Lifespan

Aligned pumps experience less stress on bearings, seals, and other components, which extends their lifespan. By reducing unnecessary wear and tear, proper alignment helps prevent premature failures and the need for costly replacements.

Reduction in Maintenance and Repair Costs

Aligned pumps require fewer repairs and maintenance interventions. By minimizing vibrations and stress on components, proper alignment reduces the likelihood of breakdowns, resulting in cost savings associated with maintenance and repair activities.

Industries that Benefit from Pump Alignment

Several industries depend on pumps for critical processes and can benefit significantly from professional pump alignment services:

Water Treatment Plants

Water treatment plants depend on pumps to transport water efficiently. Proper pump alignment ensures optimal performance, reducing energy consumption and maintenance requirements.

Oil and Gas Refineries

Pumps are integral to oil and gas refining processes. Accurate alignment is essential for maximizing productivity, preventing costly downtime, and ensuring worker safety.

Power Generation Facilities

Power plants use pumps for various applications, including coolant circulation and fuel transport. Proper alignment improves pump efficiency and reduces the risk of unplanned shutdowns.

Manufacturing Plants

Manufacturing facilities often use pumps for various purposes, such as material handling and chemical processing. Accurate alignment is crucial to maintain consistent production and prevent equipment damage.

HVAC Systems

HVAC systems depend on pumps for heating, cooling, and water circulation. Proper alignment ensures efficient operation, reduced energy consumption, and improved indoor comfort.

Frequently Asked Questions (FAQs)

-

What is the average cost of pump alignment services?

The cost of pump alignment services may vary depending on factors such as the pump size, complexity of alignment, and specific project requirements. It is recommended to contact Panpush Laser Alignment FZE for a detailed quote customized to your needs.

-

How often should pump alignment be performed?

Pump alignment should be performed during the installation process and regularly as part of preventive maintenance. The frequency of alignment checks depends on factors such as pump workload, operating conditions, and manufacturer recommendations.

-

Can pump alignment be done in-house?

Basic alignment checks can be performed in-house, but achieving precise alignment often requires specialized knowledge and equipment. For accurate results, it is advisable to depend on professional alignment services.

-

How long does the pump alignment process take?

The duration of the pump alignment process depends on various factors, including the complexity of the alignment, pump type, and the experience of the laser alignment specialized engineer. Panpush Laser Alignment FZE aims to complete alignments efficiently while maintaining high standards of accuracy.

-

Is laser shaft alignment suitable for all types of pumps?

Laser shaft alignment is a flexible technique suitable for various pump types, including centrifugal pumps, reciprocating pumps, and gear pumps. However, the practicality of laser shaft alignment may depend on the specific design and accessibility of the pump.

Conclusion

Proper pump alignment is crucial for optimal pump performance, extended equipment lifespan, and cost savings. Panpush Laser Alignment FZE provides expert pump alignment and laser shaft alignment services to various industries. With our expertise and advanced laser alignment techniques, businesses can achieve precise alignment, minimize downtime, and improve overall operational efficiency. Don’t settle for anything less when it comes to aligning your pumps.